Back

PISTON FILLERS/DEPOSITORS (190fip)

Price (excl GST): POA

Make: Hunter

Model No: 300 Series

Motor: air

Condition: New

Location: New Zealand

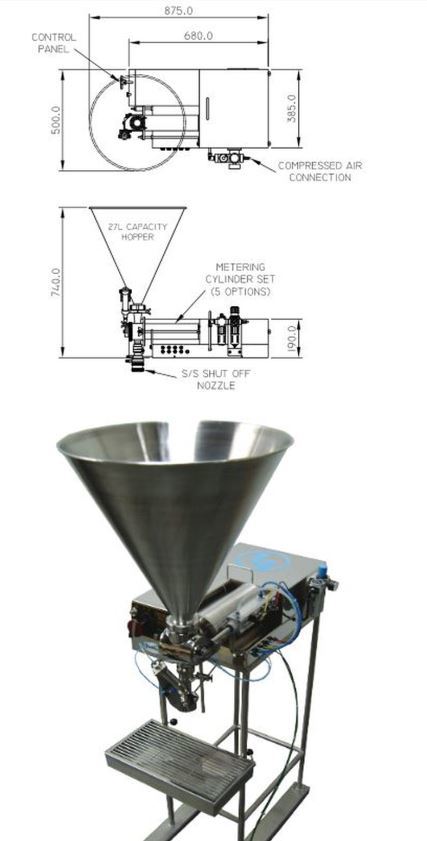

Capacity: 5ml - 2500ml

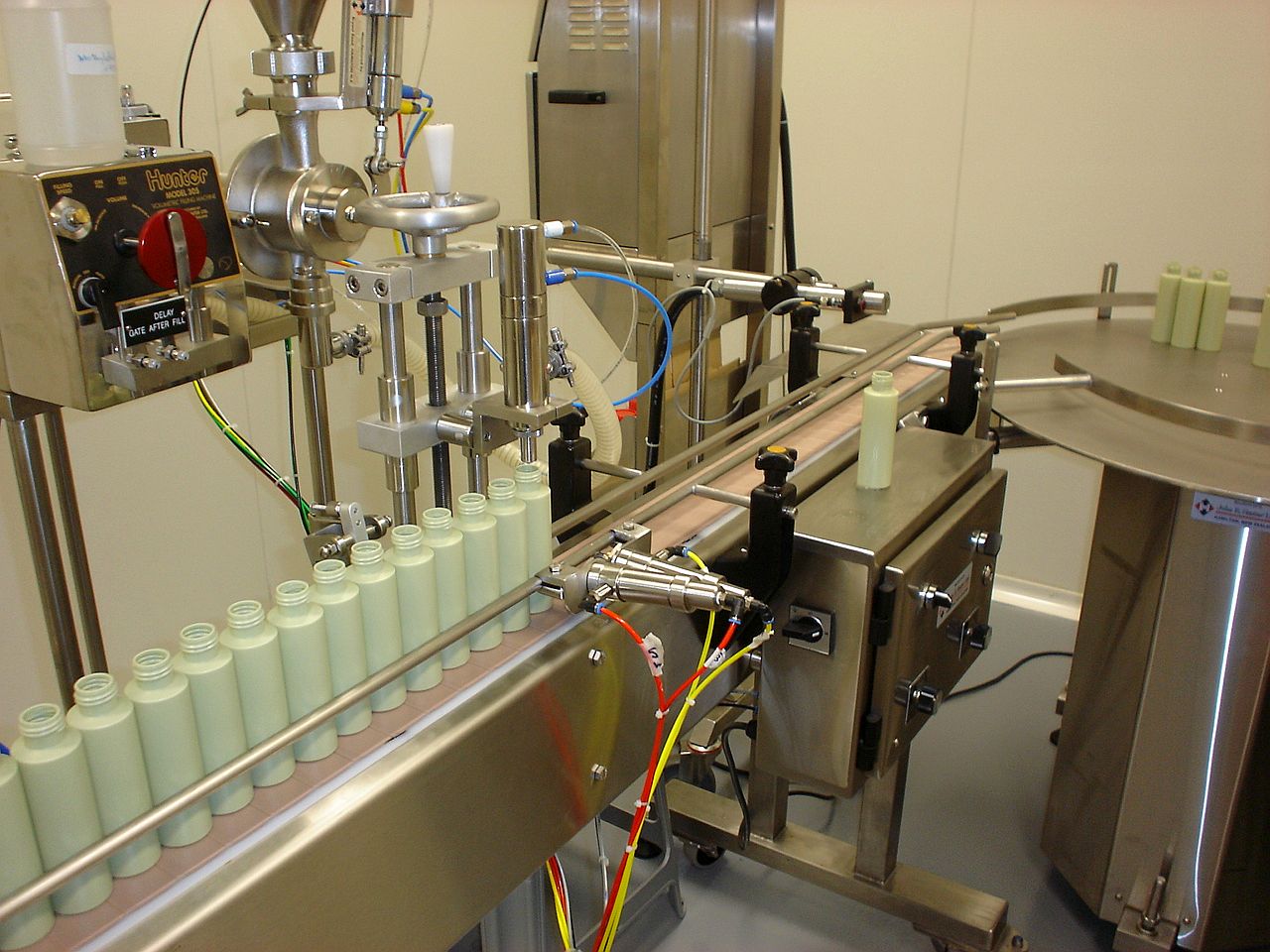

These NEW piston fillers have a volume range from 5ml to 2500ml with 5 metering cylinder options. Available as a single nozzle (Model 305) or multiple nozzles (Model 325, 335, 345). The 305 is a versatile single head, pneumatically operated volumetric (piston type) filler for accurate dispensing of liquid and semi liquid products. Construction is generally corrosion resistant, with frame and covers fabricated in T304 stainless steel. All contact parts are manufactured from T316 stainless steel or suitable plastics, allowing it to be used for such diversified products as foodstuffs and corrosive chemicals. Material may be handled hot or cold, and volumetric accuracy is usually well within +/- 0.5%.

Fills of 5ml to 2.5 litres per shot can be achieved using a range of precision-bored heavy wall metering cylinders - an optional multiple stroke mechanism is available for larger fills. The standard rotary valve has large ports, allowing passage of viscous products – and products containing pieces up to 10mm across. An optional oversize (500 series) rotary valve may be fitted, enabling the machine to handle pieces up to 20mm across. A range of non-drip shut off nozzles enables exceptionally clean filling of most products, with a sub-surface fill option available for efficient filling of foaming liquids.

The basic filler is pneumatically operated, and is completely safe in a wet (or hazardous) area. It is manufactured to strict hygiene standards, and can be easily disassembled when in-place cleaning is not applicable.

An auto gating kit is available to convert the basic semi-automatic filler to a fully automatic system suitable for auto filling on almost any conveyor.

Product feed to the filler via 27 or 50 Litre S/S conical hoppers or suction hose and non-return valve.

Versatile design using pneumatic control with foot switch or electrical initiation.

Optional multiple stroke mechanism for larger fills.

3 types of product valves available – standard rotary, large rotary and check valve.

A wide range of non-drip shut off nozzles are available with different outlets.

Optional sub-surface filling mechanism and nozzle for filling foaming products.

Can be set up as manual or fully automatic with container indexing.

A range of portable S/S stands - Low Level, Standard and Heavy Duty with adjustable height.

Products currently being packed by Hunter fillers include:

Foodstuffs:

Butter, margarine, processed cheese, yoghurt, yeast extracts, pate, jams, stews, bread dough, sauces, mayonnaise and salad dressings, peanut butter, honey, chutneys and pickles, cooking oils, fruit juices, cordials, toppings and flavourings.

Cosmetics:

Lotions, shampoos, conditioners, nail varnishes and various creams.

Other:

Detergents, disinfectants, bleaches, motor oils, printing inks, epoxy resins, paints, adhesives, caulking compounds, weed killers, garden & agricultural chemicals, veterinary and ethical supplies.

To view this style of depositor operating, please click the following links:

www.youtube.com/watch?v=4sDqUQh9P6A

www.youtube.com/watch?v=faubbXWvbLc&;list=UU_KUmyvKoqZT7f_eIu2iwlA&index=72 - shows bottom up filling for foaming products

www.youtube.com/watch?v=xcHB8I86NIg&;list=UU_KUmyvKoqZT7f_eIu2iwlA&index=112 - with handheld dispensing nozzle

www.youtube.com/watch?v=XYzszcwvcN8&;list=UU_KUmyvKoqZT7f_eIu2iwlA&index=94 - depositing aerated product (ice cream)

www.youtube.com/watch?v=LO8vIxgysJE&;list=UU_KUmyvKoqZT7f_eIu2iwlA&index=114 - doing 5 bottom up filling for products that foam